History of the Compound Bow

History of the Compound Bow

History is unfolding before us within every present moment. The story of archery and its history is no exception. New technologies, methods, and insights into the bow and arrow are still occurring. While it is true that archeryhistorian.com does take a special interest in archery as it was practiced in ancient and medieval times, we cannot ignore some relatively recent advancements in bow technology and use. That is why, in this article, we will take a close look at the history of the compound bow.

First, we will answer some important questions to lay the groundwork for further exploration. What is a compound bow? How does it work? Who invented it and when? All these questions will be addressed more as we delve into the history of the compound bow.

History of the Compound Bow – What is a Compound Bow?

First of all, in its fundamental physical sense, what is an archery bow? In its simplest and most mechanical definition, a bow is an energy storage and transfer device. The energy of your muscles is transferred through the string when you draw it and into the limbs of the bow. Upon release of the string, this energy stored in the limbs is then transferred to the arrow via the string. Could there be a way to use some basic principles of mechanics to enhance this energy storage and transference? The answer is yes, and in the late 1960s, a certain Holless Wilbur Allen (July 12, 1909, Stilwell, Kansas – June 28, 1979, Billings, Missouri) demonstrated how this could be done.

A compound bow is a mechanical bow. That is to say, it uses some basic principles of mechanical leverage to enhance energy storage and transfer First some information on the naming of these modern bows. Why are they called “compound bows”? There may be some confusion in the naming so let us clear that up here.

The word compound, according to the Merriam-Webster dictionary refers to something formed by a union of elements or parts. While it is true that a compound bow is made from a combination of different parts or components, the word compound actually refers to the type of pulley system installed on the bow.

Cams & Pulleys

This type of pulley system uses a combination of fixed and movable pulleys and forms a block and tackle. This pulley system and the cams at the ends of a bow’s limbs are what make it a so-called compound bow. We will go over more specifics of how a compound bow works in the following section.

For simplicity’s sake, we may simply define a compound bow as an archery bow that uses cams and a system of pulleys to mechanically enhance its performance.

How Does a Compound Bow Work?

Before we delve into the proper history of the compound bow, its inventor, and its commercial success, let us first discuss the functionality of the compound bow. How exactly does it work?

If you were to extract an archer from ancient times or medieval times, say, an English longbowman from the 1300s, and show him a modern compound bow, I would think he would view it as quite a complicated device. Compared to the English longbow, it is indeed more complicated in its design, manufacture, and function. However, the fundamental mechanism(s) behind the operation of a compound bow is in fact relatively simple.

Leverage

As the Greek mathematician, Archimedes famously said “Give me a lever long enough and a fulcrum on which to place it, and I shall move the world.”

The concept and use of mechanical leverage go back many millennia. There is evidence in ancient Egypt as far back as 4000 BC. The idea can be summarized by several simple concepts.

E(energy applied) = F(force) x D(distance)

Knowing that you can manipulate (preferably multiply) the energy applied to a system by increasing not the force applied, but rather the distance over which that force is applied is the key to the compound bow.

If you can understand what is happening in the above image, you will be able to understand the mechanics and/or function of a compound bow. There are only four things present.

- 100 kg ball

- 5 kg ball

- plank of wood (lever)

- fulcrum (what the plank of wood and balls are balancing on)

Can you move or lift the 100 kg ball with a 5 kg weight? Yes, you can! You just have to increase the distance from the fulcrum to the 5 kg ball (or decrease the distance from the fulcrum to the 100 kg ball). That’s it. The principle of mechanical leverage.

Leverage & The Compound Bow

Having understood the basic idea of leverage, let us expand on the concept and apply it to a compound bow.

When you first look at a compound bow, one of the first things many take note of is the strange wheel-like devices on either end and the cable system connecting them. These wheels at the end of the bow limbs are called cams. This is where the magic of leverage takes place in a compound bow.

The cams at the ends of a compound bow consist of an outer wheel (A) and an inner wheel (B). They are attached to the same axis. As you can see from the diagram, the distance from the center of wheel A to its edge (radius) is larger than the distance from the central axis to wheel B’s edge. By the same force multiplying mechanism of leverage, we discussed earlier, if a force (in this case the archer pulling and drawing the string) is applied to wheel A, a greater force will be applied to wheel B, determined by the ratio of the diameter of the wheels or cams. This setup is known as a block and tackle. Now let’s add another cam to the lower limb and we can get the full picture.

Force Multiplication in Action

Putting it all together we see that the limbs of the bow attach to the axle of the cam. There is a cable between the smaller inner circles. This cable is attached to the center of the opposing wheel. Now as the archer pulls back the string, rotating the larger wheel, the inner wheel will also rotate, but because of its smaller diameter, with a greater force.

Drawing the bow will also exert a force on the smaller wheels, pulling them closer together. This, in turn, puts tension on the limbs of the bow, bending them and storing energy. The limbs of the bow are attached to the axle as well. And there you have it, a way to mechanically enhance the energy input storage of a bow. There is one other important aspect of a compound bow other than its force multiplying effect. This is known as let-off. We will discuss this in the next section.

History of the Compound Bow – Let-Off

Anyone that draws a compound bow to full draw for the first time will notice something very interesting. The tension or weight of the bow increases at the beginning, then levels off, and then drops off considerably. Some compound bows can reach a let-off of 80% or even 90+%! That means that if a compound bow with a 100-pound draw weight with an amazing 90% let-off, the archer will feel a draw weight of only 10 pounds when they reach full draw. This is extremely convenient when taking aim and trying to be as accurate as possible. It obviously takes much less effort to hold 10 pounds while taking aim than 100 pounds!

But how is this accomplished? How can a bow, as if by magic, transition from a peak of 100 pounds to only 10? No magic. Just some more ingenious engineering and some physics.

Eccentricity

The astute observer would notice that at least one of the cams (possibly both) is not quite perfectly circular. Indeed this is correct. The cams are eccentric, not perfectly circular but more egg-shaped or ovals. The shape is very specific to allow an increase in the distance from the central axis when the compound reaches full draw. As we have discussed in the above sections, increasing the distance to the fulcrum or axis, increases leverage. This increase in leverage at the last moment is what allows for let-off. A diagram may illustrate the point with more clarity.

Compound Bow Cam @ Start of Draw Cycle

As you can clearly see, the distance from the central axis to where the string or cable makes contact on both the inner and outer wheel is roughly the same. The outer wheel (cam) has a slightly larger distance from the axis to the edge where the string makes contact.

Compound Bow Cam @ Full Draw

Now as you can clearly see from the diagram above when the bow is at full draw, the relationship of these distances is not the same. The outer (orange) “wheel” has a much larger distance to the axis. This increase in distance increases leverage and the compound archer will experience this as let-off.

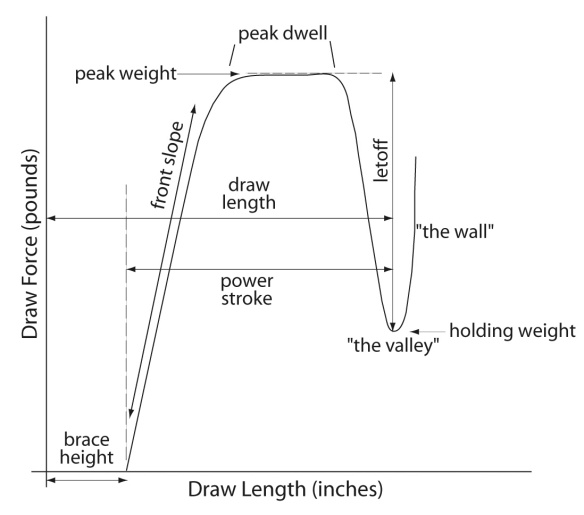

You can see how this relationship manifests itself in a force-draw curve. This is where the draw distance is plotted against the draw weight at that distance. For a conventional recurve, the relationship is more or less linear.

As you can see from the above diagram the force-draw graphs are not perfectly linear, but draw weight increases predictably as you increase the draw length of the bow.

Now check out a force draw curve for a modern compound bow.

As you can clearly see, the force required to hold the bow at full draw is diminished significantly. This area of diminished force is commonly known as “the valley”.

History of the Compound Bow – Cam Configurations

- Single Cam (Solo Cam): This configuration utilizes a single cam at the bottom of the bow and an idler wheel at the top. The cam and idler wheel work together to control the draw length and provide a smooth draw cycle.

- Dual Cam (Twin Cam): Dual cam bows feature two cams at the top and bottom of the bow, which are synchronized to ensure consistent performance. These cams work in opposite directions, and the string is attached to both cams. Dual cam configurations offer high arrow speeds and accuracy but may require more maintenance and tuning.

- Hybrid Cam (Binary Cam): Hybrid cam bows use a combination of a single cam and a power cam or two elliptical cams. This configuration aims to provide the benefits of both single and dual cams, such as smooth draw cycles, speed, and accuracy. Hybrid cam systems are often adjustable, allowing archers to customize their draw length.

- Cam and a Half: This cam configuration combines a binary cam on the bottom limb with a single cam on the top limb. The single cam reduces cam lean, while the binary cam offers better speed and accuracy. Cam and a Half systems can provide a balance between performance and ease of tuning.

- Quad Cam (Four Cam): Quad cam bows incorporate four individual cams, with two on each limb. These cams work together to distribute the load evenly and reduce string torque. Quad cam configurations are known for their exceptional stability and accuracy but may require more maintenance and setup time.

- Hinged (Swing) Cam: Hinged cams feature a hinge mechanism that allows the cams to swing away during the release, reducing string interference and improving accuracy.

For more, please check out our article on the physics of archery here.

History of the Compound Bow – Who Invented the Compound Bow?

Now that you’ve become familiar with what a compound bow is and how it works, let’s discuss the history of the compound bow. Who invented it?

The history of the compound bow can be attributed to the invention of one man: Holless Wilbur Allen, Jr. There is not much information on his early life.

He was born on 12 July 1909, in Stilwell, Johnson County, Kansas, USA. His parents’ names are Holless Wilbur Allen (Senior) and Luella Beatrice Williams Allen. As we mentioned, there is nothing much recorded about his early life, but he did graduate high school unlike his father before him who apparently only achieved a grade 6 level education.

After school, Holless Wilbur Allen moved to Gallatin and took up a job as a salesman for a wholesale hardware store. Eventually, he started his own business making steel wire basket frames for the floral industry.

Holless apparently was an avid deer hunter and enjoyed fishing. It was his repeated frustrations with the hunting bows of his day and his lack of success in hunting dear that inspired him to consider designing and building his own.

History of the Compound Bow – The Prototype

Holless experimented with several designs to improve or enhance the energy delivered and speed of the arrow. He worked on extremely recurved tip designs and bow designs with a rail attachment to guide a light arrow toward the target. There were many initial failures as penetration was poor and prototypes were damaged. After carefully reading some material on kinetic energy from his youngest son’s high school physics textbook he was inspired to produce another design.

This involved cutting off the tips of a recurve bow that he had on hand, and he mounted a small standard aircraft pulley into the notched ends of a homemade bow. This formed a simple “block-and-tackle-like” pulley device. The rear string span on this arrangement served as the bowstring. Unfortunately, still no luck. He could not get the speed and penetration enhancements he was after. There must be a way.

Holless Wilbur Allen – Mechanical Inventor

Although not formally trained as an engineer or mechanic Holless Wilbur Allen seems to have had a strong interest and competence with various mechanical devices. Several examples of his mechanical aptitude stand out. As mentioned, he went into business for himself, making metal wire baskets for the floral industry. The equipment used to manufacture the baskets was all custom-made by Holless. He built a machine for straightening and cutting lengths of wire taken from a 200-pound spool. This was all done automatically. The machine was built from assorted components including parts from two washing machines he purchased at a junkyard. Apparently, the cost of one of these wire-cutting machines at the time was over $50,000 however with some ingenuity and mechanical talent, Holless was able to assemble a working version of this machine for $20.

Another incident showcasing Holless’ mechanical tinkering talent involved the disassembly of a new 35mm German-made reflex camera. The camera apparently belonged to his sister, who surely brought it over to take pictures of a family Christmas gathering. Curiosity having got the better of Holless disassembled it to find out how it worked. His wife being appalled at the dismemberment of the new camera became frantic. At this point, the camera was promptly reassembled in perfect working order with his sister being none the wiser.

History of the Compound Bow – A Breakthrough

One evening in 1966 while contemplating his older bow design attempts Holless Wilbur Allen finally had his breakthrough. What if he made the cam’s pivot points off-center? This was surely it! Within two days he had built what could be considered the first modern compound bow. It was a crude prototype, especially by today’s standards, but it achieved the desired effect.

The eccentrics (cams) were fashioned from wood, while the riser was made of pine boards and the limbs of laminated oak flooring and fiberglass. This was all held together by several bolts, nails epoxy, and glue.

He applied for a patent on June 23, 1966, and U.S. Patent 3,486,495 was granted to him in December 1969.

His new bow design quickly gained popularity. By 1977, there were 100 different models of compound bows available, only 50 recurve models. After only ten years of production, two-thirds of the available choices were compounds. After some convincing, game agencies approved the bow for hunting, and soon afterward archery organizations approved the bow for tournament shooting.

Nowadays, in the USA, the compound is the most popular bow, especially for hunting.

Most first-time compound buyers (74%) said their next bow would be a compound, which makes sense. Compounds are the most popular bow type for all generations. Over 75% of surveyed bowhunters own and use compounds. Millennials have the highest rate of compound-bow users (92%), compared to Gen X-ers (84%) and baby boomers (68%).

credit: https://archerytrade.org/survey-results-bow-preferences-and-buying-habits-for-three-generations/

When Were Compound Bows Invented?

1966. The inventor, Holless Wilbur Allen applied for a patent on June 23, 1966, and U.S. Patent 3,486,495 was granted to him in December 1969. The rest, as the saying goes, is history.